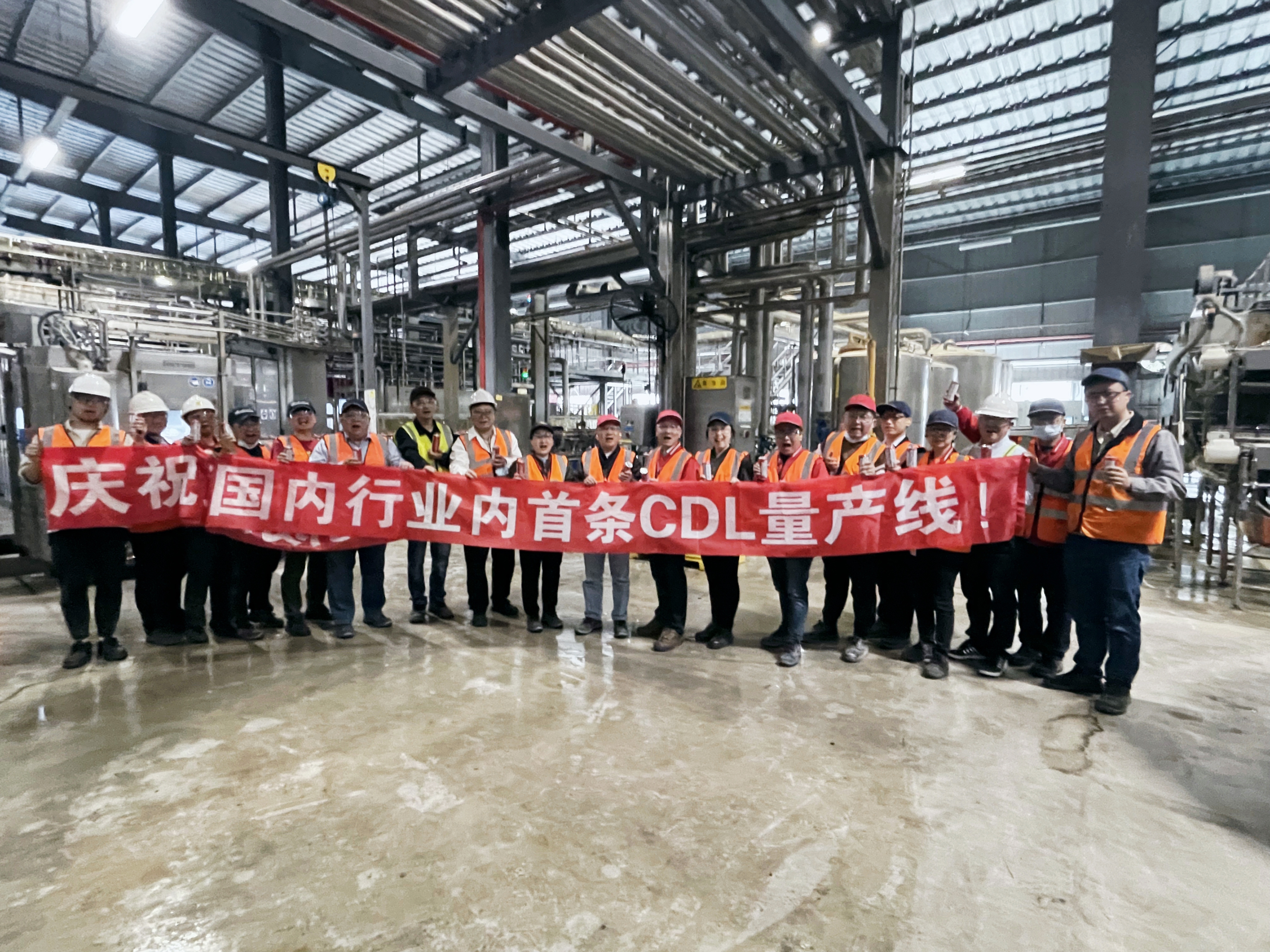

On March 14, 2023, the CAN3 line of Budweiser Wuhan factory successfully completed the switching of lightweight covers, marking the official production of lightweight cover packaging line in the domestic industry.

ORG, as a strategic partner supplier of Budweiser, attended the switching ceremony of CAN3 line at Budweiser’s Wuhan factory.

The birth of Budweiser Wuhan lightweight lid batch production line not only represents a technological breakthrough in the field of lightweight lids in China, but also has a very positive significance for the green and sustainable development of the domestic metal packaging industry.

“Double Carbon” Driven

Data shows that packaging accounts for up to 40% of garbage, and the recycling rate in garbage is 50%.

Indeed, the concept of “mountains of gold and silver are not as good as green waters and mountains” has deeply rooted in people’s hearts, and green development has become an important driving force for economic growth and social development.

The reduction in resource demand and consumption, the cost of bottle cap materials, and the reduction in carbon emissions generated during transportation and production processes are all contributing factors to green development.

Therefore, the low-carbon development of the packaging industry is not only about pollution control and emission reduction in a simple sense, but also requires systematic changes in industrial structure and production methods.

Under the enormous pressure of the current “dual carbon” policy goals, the lightweight of both the tank body and lid is an urgent technical requirement for metal packaging production enterprises.

As a witness and participant, ORG attended the birth of the lightweight lid packaging line in the domestic industry, which represents the deep cooperation between the two sides in this field in the future.

“Lightweight” in the Future Trend

Lightweight has always been one of the trends in China’s metal packaging industry.

Taking two piece cans as an example, ten years ago, two piece cans were still dominated by # 206 can diameters, but were replaced by # 202 or even # 200 can diameters just a few years later.

The development trend of covers is the same as that of cans.

The lightweight cap technology has been proven for about 12 years abroad and has become very mature, with a usage of over 700 billion units.

Compared to the widely used B64 easy to open lids in the industry, lightweight covers can achieve the same performance through optimized design with fewer aluminum materials used.

The application of lightweight covers is not only a highlight of the progress of the “lightweight” trend in the metal packaging industry, but also a technological breakthrough in the lightweight development of domestic metal packaging.

For many years, ORG has been actively exploring the path of “weight reduction” for cans. On the basis of ensuring the pressure resistance of the two piece can products, it has completed the first sample testing and batch trial of appropriately reducing the thickness of the aluminum cover and the cover pull ring.

Sustainable Development is Bound to Lead to a Win-win Result

As a leading enterprise in metal packaging, ORG has been continuously deepening its efforts on the path of green and environmentally friendly sustainable development.

In actively promoting China’s use of related green materials, ORG has reached an international advanced level. Not only that, but ORG has also been promoting the recycling and reuse of metal packaging and seek green development momentum.

Since joining the Budweiser Strategic Cooperative Supplier Alliance (SSA) project in 2021, ORG and Budweiser have conducted in-depth cooperation and integration in various aspects. Origen (Foshan) has also won the “Best Supplier” award from Budweiser Strategic Cooperative Supplier Alliance multiple times.

Moreover, as the core supplier of cans to Budweiser Asia Pacific, ORG has 8 factories supplying cans to Budweiser.

The mass production of the lightweight cover packaging line at Budweiser Wuhan factory this time will also bring deeper and more diversified possibilities for future cooperation between the two parties.

In the foreseeable future, the cooperation between the two sides in the field of lightweight covers is bound to ignite a new technological whirlwind in the metal packaging industry.

“Lightweight” is Beyond “Lightness”

Nowadays, both brand and consumer products with environmental attributes are increasingly favored and valued, and lightweight products have more advantages beyond environmental protection and “lightness”.

In terms of brand, the lightweight packaging of the overall product has obvious advantages in production, canning, transportation, and other aspects, which can help enterprises save overall production, procurement, and transportation costs.

In terms of consumption, lightweight product packaging not only has the environmental elements that consumers like, but also brings a lightweight, comfortable, and portable user experience to consumers.

The changes in consumer demand for products and packaging can be said to determine the development direction of packaging innovation. In the trend of green and environmental protection, lightweight packaging will also be a new boost to brand competition.

ORG, which is well aware of this, has been breaking through and never stopping on the path of providing consumers with more convenient packaging methods and higher recycling rates of metal packaging.

In the future, in the field of lightweight metal packaging, ORG will definitely become a technology leader.