Holding a bowl of “Runcongtang” red bean paste, it is cold to the bottom of my heart, but warm in my heart.

In July 2022, “Runcongtang” and “Tangerine Peel Lotus Seed Red Bean Paste” were officially launched on Sam’s Club’s shelves, and a year later, “Tangerine Peel Lotus Seed Red Bean Paste” has become a long-term praise item on Sam’s Club’s popular list due to its soft, creamy, cold and refreshing taste.

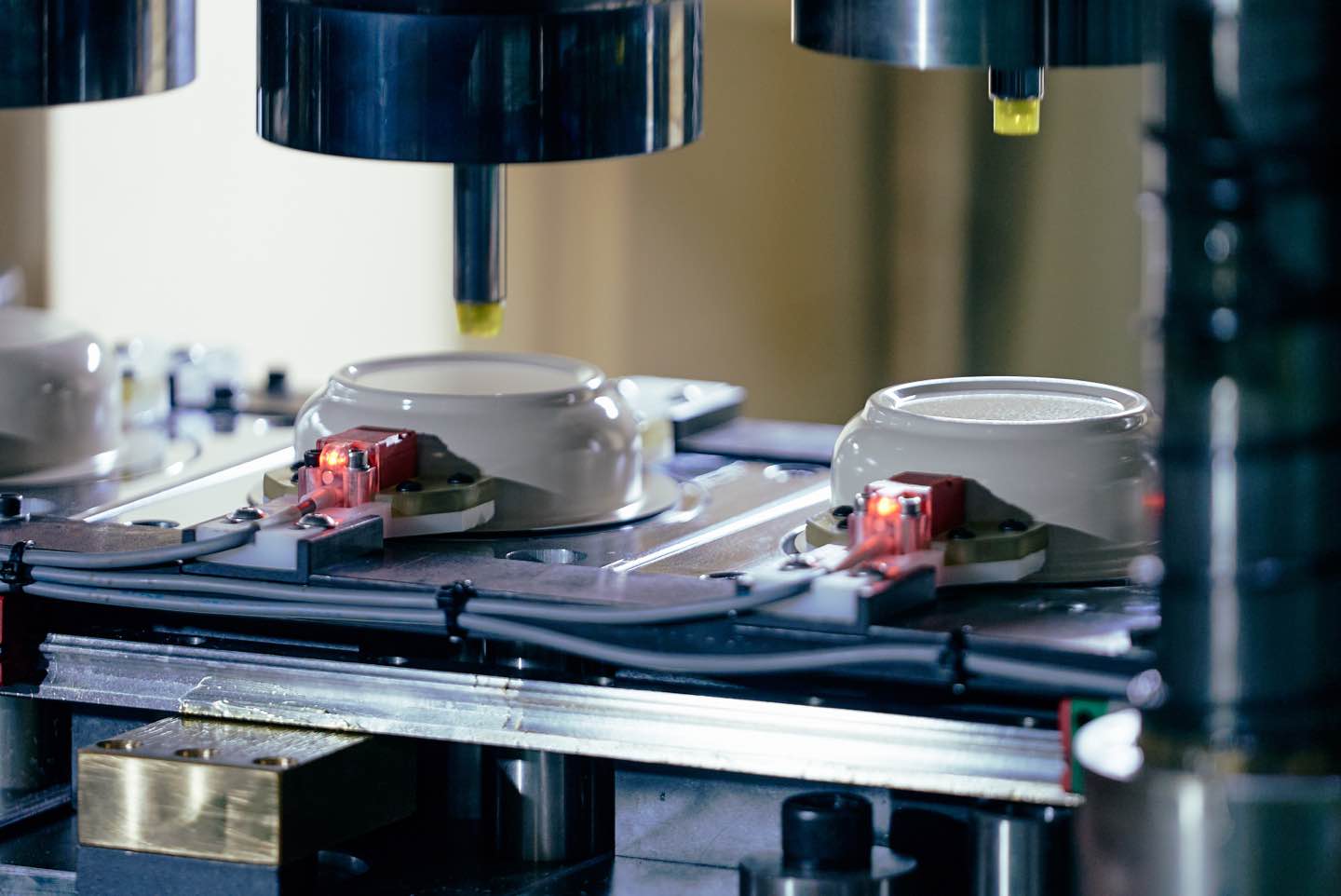

A single popular single product has brought fire to ORG’s bowl and jar products, and also brought fire to the development of the concept of sustainable development in the metal packaging industry.

Subsequently, the “Runcongtang” brand once again launched buffalo milk jade bamboo mung bean paste and tangerine peel lotus seed mung bean paste, both of which became popular products in this summer.

The data of the “ORG Bowl” in the first eight months of 2023 has tripled compared with the whole of 2022, thanks to the popularity of these products. This cooperation has also become a typical case of the collision between FMCG fashion and life aesthetics in the industry.

Showing the edge of the bow and opening a small victory

A popular FMCG model is indispensable, with the right time, the right place, and the right people.

The producer of the “Runcongtang” brand is Dazhou Xinyan. A few days ago, Zhou Yunjie, Chairman of ORG Technology Co., Ltd., Chen Yufei, Senior Vice President and General Manager of Innovation Division, Ma Binyun, Vice President and General Manager of Two-Piece Can Division, Chen Zhongge, Vice President and General Manager of Three-Piece Can Division, and Zhang Liangde, Vice President and Director of the Chairman's Office, just visited Dazhou Xinyan.

Zhou Yunjie and his entourage, together with Shan Yongjun, founder and general manager of Dazhou Xinyan (Xiamen) Biotechnology Co., Ltd., Deng Wandong, deputy general manager of the manufacturing center, Chen Jialuo, director of the quality control center, and Su Jinzu, director of the production center, made detailed arrangements for the future cooperation between the two sides in the field of FMCG.

It is no accident that the two sides reached a strategic cooperation, the main production base of Dazhou Xinyan is located in Xiamen City, Fujian Province, as early as October 2014, ORG established Zhangzhou ORG Packaging Co., Ltd., specializing in the production of food cans.

In terms of geographical location, ORG has more than 30 production bases across the country, as well as an advanced can-making, filling and other production lines in China, forming a grid industrial radiation capacity. This makes it not accidental that ORG and Dazhou Xinyan met in the geographical dimension.

Whether it is the acquisition of Ball Asia-Pacific’s production capacity in China, or the subsequent increase in Yongxin shares, and then the acquisition of Australian metal food cans and aluminum aerosol can packaging Jamestrong, ORG’s main business service capabilities are constantly strengthened.

The launch and popularity of the “ORG Bowl”, and even the report card of 17.584 billion cans sold by ORG in 2022, not only rely on this location service capability.

In the past 30 years, ORG has relied on the research and development of cutting-edge technologies in the industry, the research and development and application of innovative materials such as coated iron, the continuous innovation in the design of new tank types, and the continuous cultivation of information service marketing and sports marketing, which has also built a second competitiveness moat for ORG.

The research on coated iron technology started in 2008, and the 15 years of consistent investment have fully demonstrated that the industry operators have strategic determination to stay at the forefront of market changes.

Race against time to be close to the service

The ability to perceive industrial changes, the efficiency of responding to market demand, and the demand response to FMCG brands are the internal skills that metal packaging companies need to cultivate. ORG proposes a “factory-in-factory” type of close supply service, and uses its existing business endowment to provide customers with comprehensive packaging services.

In the cooperation with Dazhou Xinyan, the tireless pursuit of “internal strength” has enabled the two sides of strategic cooperation to work together to cope with a series of changes in the market.

In July 2023, Chen Yufei, senior vice president of ORG, received a request from sales manager An Peiyuan about the additional order of “Runcongtang”, and the company’s management, to regional subsidiaries, and then to front-line engineers responded quickly, starting a beautiful battle against time and close to service.

Since ORG’s bowl and jar production capacity in Zhangzhou, Fujian Province has been full, only a new production line can solve the new demand of “Runcongtang”. According to the normal process, it takes at least half a year for the production line to be designed, customized, installed, debugged, and verified, and the customer cannot wait, and the market cannot wait.

But it is imperative to provide quality and quantity products in the shortest possible time. The company's management weighed the pros and cons and decided to “relocate the Shaoxing bowl and can production line to Zhangzhou for rectification”, Zhai Junwei, deputy general manager of Zhangzhou company, immediately rushed back to Zhangzhou from Beijing, and the project team was set up by Shaoxing company and Zhangzhou company to prepare for the relocation and rectification of equipment at the first time.

From the establishment of the working group on July 7th to the overall delivery of the equipment to the Zhangzhou factory on July 9th, the Zhangzhou factory director Lv Shiyun has completed all the preparatory work before installation with the engineers. Shen Weiwei, an equipment engineer of the R&D center, not only proposed the overall transportation plan, but also personally operated the operation. This saves half a month of time compared with the transportation of disassembled parts. Chen Yufei, senior vice president, and Li Zhong, general manager of the food can project department, commanded the installation on the front line. At the same time, the sales manager An Peiyuan has synchronously arranged the scheduling of production materials to ensure that the equipment can be put into production immediately after commissioning. In three days and three nights, a new production line was installed in the ORG Zhangzhou factory.

On July 14th, the whole line was connected to the small batch test, rectification and adjustment; on July 16th, the medium batch test machine, the new line safety and quality control training; on the morning of July 19th, after multiple rounds of testing and verification, the first batch of coated iron bowl cans of the new line to ensure that they were qualified were loaded and sent to the “Runcongtang” factory.

It seems that the “impossible task” has been seized from the market for more than half a year under the unity and energetic offensive of ORG people.

This fully proves the concept and ability of “packaging brand, brand packaging”. The list of ORG's strategic cooperation includes a number of leading brands such as Red Bull, Feihe, Coca-Cola, PepsiCo, Tsingtao Beer, Budweiser and Yuanqi Forest, which is not as simple as the market seems.

The spirit of enterprise breaks the cocoon into a butterfly

Innovation and development are not only a matter of ability, but also a matter of responsibility and courage, when faced with risks and challenges, we must have the courage to try, dare to take responsibility, and only in the tempering can we “break out of the cocoon into a butterfly”.

Since 1994, ORG has been in business for 30 years, and ORG people have never lacked this spirit.

During the relocation of the “ORG Bowl” production line, ORG responded quickly and worked together from the company’s managers, to the heads at all levels, engineers and front-line workers, and raced against time in the 40-degree high temperature weather in the south in summer, which reflects this spirit.

From another point of view, the product design of ORG bowls is round and lovely, simple and back to basics, in fact, it also reflects ORG’s pursuit of dedication, professionalism and natural carving.

Chen Yufei, vice president of ORG, pointed out that innovative products and innovative services build an innovative model, and ORG pursues to continue to empower customers in the fast-growing market.

This is one of the original intentions of ORG’s strategy for the development of “packaging +” in recent years.

According to the content of the meeting between Zhou Yunjie and Shan Yongjun, the two sides have initially reached cooperation in the field of new products.