How light can a "can" be made?

A scale was placed in the most prominent spot at the launch meeting of the "Budweiser Asia-Pacific Sustainable Journey of Aluminum Can Carbon Reduction" Summit on October 27th. One can weights the same as 4 ping pong balls!

Currently, the weight of a 330-mL lightweight can has reached 9.57 grams; the goal is to reach 9.3 grams within three years for the same size cans. Zhou Yunjie, Chairman of ORG Technology, commented. ORG Technology is the packaging provider for Budweiser and a leading domestic metal-packaging company.

Zhou Yunjie also discussed the carbon reduction transformation of the beer and the entire FMCG industry,pointing out that this initiative not only requires individual enterprises to persistently optimize environmental-friendly production processes, but also calls for collaboration between ecological partners to enhance low-carbon technology innovation, improve technology reserve levels, and build a low-carbon industrial ecology.

Building Synergy: a good solution for sustainable development of cans

The summit was held at the "Budweiser-China Beer Museum" in Putian, Fujian. As one of the second group of 18 cities earning the title "Investment Hotspot Cities in China", this small coastal city in the "Golden Corridor" of Fuzhou-Xiamen has become a focal point for innovation and development of the domestic beer industry.

Finding out how the FMCG industry can reduce carbon emission in aluminum can production is the main purpose of pioneer representatives from the manufacturing, R&D, and investment sectors of the industry. Focusing on the "can", a vigorous green revolution has gradually been unveiled.

Zhou Yunjie pointed out that metal packaging connects the FMCG brands and resource companies. It is the most traditional resource-consuming business. This also makes metal packaging companies a critical link in achieving China's carbon peaking and carbon neutrality goals. The resource consumption and energy consumption of metal packaging companies impact the energy consumption and resource consumption of ordinary consumers.

Based on the amount of annual global consumption of 400 billion cans, for every 1 gram reduction in the weight of cans, the weight of resource consumed alone will be reduced by 400,000 tons, excluding consumption savings in the production process.

Budweiser Asia-Pacific, working with partners such as ORG, reduced the weight of cans by optimizing the design of cans and using lightweight lids to create light and low-carbon "Lightweight Cans" while ensuring the safety in use. This initiative alone has saved approximately 2,700 tons of aluminum so far.

This is why a small can has become a key breakthrough for the FMCG industry to promote the ecological carbon reduction transformation.

Zhou Yunjie said that the two parties have achieved "carbon emission reduction" through technological innovation and process innovation, which has not only brought social benefits, but also reaped tangible economic benefits. ORG and Anheuser-Busch have already carried out carbon emission assessments at their Foshan and Xianning factories to prepare for the next step of carbon emission reduction and carbon neutrality.

Multi-faceted approach: Diverse Possibilities of "Sustainable Journey of Can Carbon Reduction"

ORG's experience has proven that investment in sustainable development strategy is not a cost item, but a "moat" to strengthen the core.

The most important part of ORG's transformation from a can-making supplier to a comprehensive packaging solution provider is to promote the formation of new green development momentum in the metal packaging industry through technological, service and model innovations.

Zhou Yunjie said frankly that ORG has invested heavily in green technology development and green project promotion, which met some disagreement in the industry in the early years. However, in the past three years, many strategic partners in the FMCG industry, including Anheuser-Busch, have put forward carbon emission reduction requirements. This has enabled the early strategic deployment by ORG to be quickly transformed into productivity.

Taking coated iron as an example. ORG started its research and development in 2007 and was able to break the foreign technology blockade and fill the domestic technology gap for coated iron and its application within 16 years,. In the production and application process, coated iron packaging can reduce carbon dioxide emissions by 69.95%, reduce solid waste by 99.7%, reduce energy consumption by 68.89%, and save industrial water consumption and tin resource consumption. It has become a popular choice in the FMCG sector.

Planning the future together: Take one small step more and “CAN” see a new future

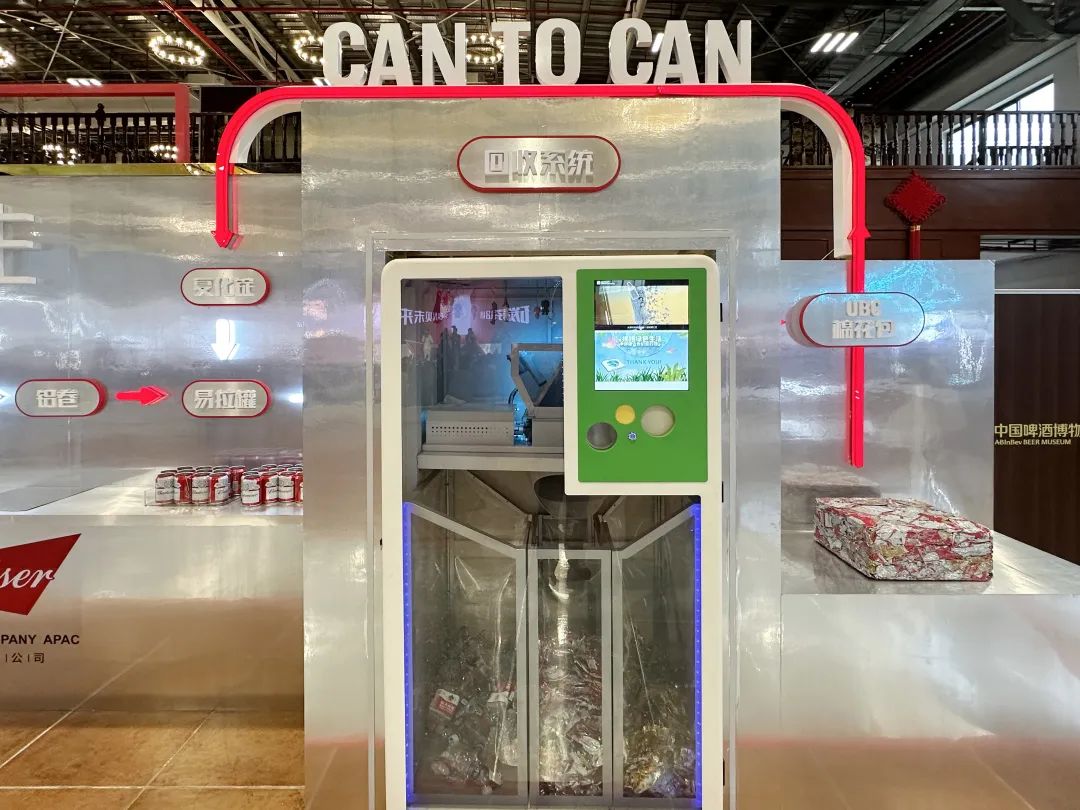

From the research and development of lightweight cans, the development of can recycling machines, the development and application of coated iron technology, the "Green Packaging Alliance" initiative, and the operation of “Youban" partnership recycling projects, they all consistently stick to the ORG's original intention of committing to the ecological construction industry.

Zhou Yunjie believes that in the past, the top priority of entrepreneurs was "to make profits." However, faced with the choice between "profit" or "sustainable development," he believed that "sustainable development must be prioritized."

The industrial advantages formed under this model are the “competitive advantages of sustainable development.”

Zhou Yunjie pointed out that we need to take corporate responsibility, development responsibility and historical responsibility more seriously.

It is reported that by hosting this summit, Budweiser Asia Pacific aims to join hands with the industry chain and policy-makers to promote the establishment of a systematic solution for the same-level recycling and reuse of aluminum cans, promote the standardization of the recycled aluminum industry and improve the quality and efficiency of the non-ferrous metal industry, and contribute to the high-quality development of the circular economy.