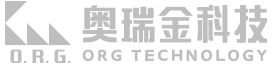

ORG Technology Co., Ltd. has recently released a carbon footprint report for its two-piece cans, which has been verified and certified by a professional domestic certification agency.

In light of China's "dual carbon" goals, the term "footprint" vividly illustrates the concept of examining a product's entire life cycle. Carbon footprints are becoming a powerful tool in China's green and low-carbon transformation efforts.

As a metal packaging manufacturer, ORG occupies a crucial position in the fast-moving consumer goods (FMCG) packaging industry chain. Our role extends beyond being merely a product and service provider; we see ourselves as pioneers in driving the FMCG industry towards a greener, low-carbon, and sustainable future.

The two-piece can carbon footprint report released by ORG offers an in-depth analysis of the life cycle carbon footprint for both individual cans and one-ton batches. This comprehensive report demonstrates our emission reduction capabilities throughout the entire process, from raw material sourcing to manufacturing and transportation.

Innovation at Birth: Engineering Lightweight, Low-Carbon Excellence

Lightweight design is a highly effective strategy for reducing carbon footprints.

Given that 400 billion cans are consumed globally each year, reducing the weight of each can by 1 gram would result in a 400,000-ton reduction in finished can weight, even without accounting for reductions in the production process.

ORG's two-piece cans are a testament to our advanced technology.

From the initial design stage, we optimize can body structure and use lightweight lids to reduce overall can weight while ensuring safety, resulting in low-carbon "lightweight cans".

Taking ORG's lightweight cans created for Budweiser as an example, weight reduction has been achieved in both the can body and lid.

The 330ml standard can body weighs a mere 9.57 grams, and we plan to further optimize this to 9.3 grams within the next three years - an advanced level in the industry.

In 2023, we made a significant leap forward with can lids. We officially launched a lightweight lid packaging line that represents a major technological breakthrough in the domestic market.

In our partnership with Budweiser alone, our lightweight cans have reduced aluminum usage by approximately 2,700 tons.

ORG has firmly established itself as an industry leader in lightweight design for material saving and carbon emission reduction.

Sustainable Growth: Nurturing Green Practices for Carbon Reduction

The Report highlights two areas with relatively high proportions of carbon emissions: the production and manufacturing stage, and emissions generated by purchased electricity. ORG demonstrates strong performance in both these critical areas.

The Xianning factory serves as an excellent example of ORG's commitment to reducing emissions. The implementation of the Dianzhangmen (an energy-saving system) and rooftop photovoltaic power station projects has resulted in significant energy savings. Our Dianzhangmen system alone saves 860,000 kWh of electricity annually. Furthermore, the photovoltaic power station generates approximately 5 million kWh per year, with an impressive self-use rate of 89% of the total power generated.

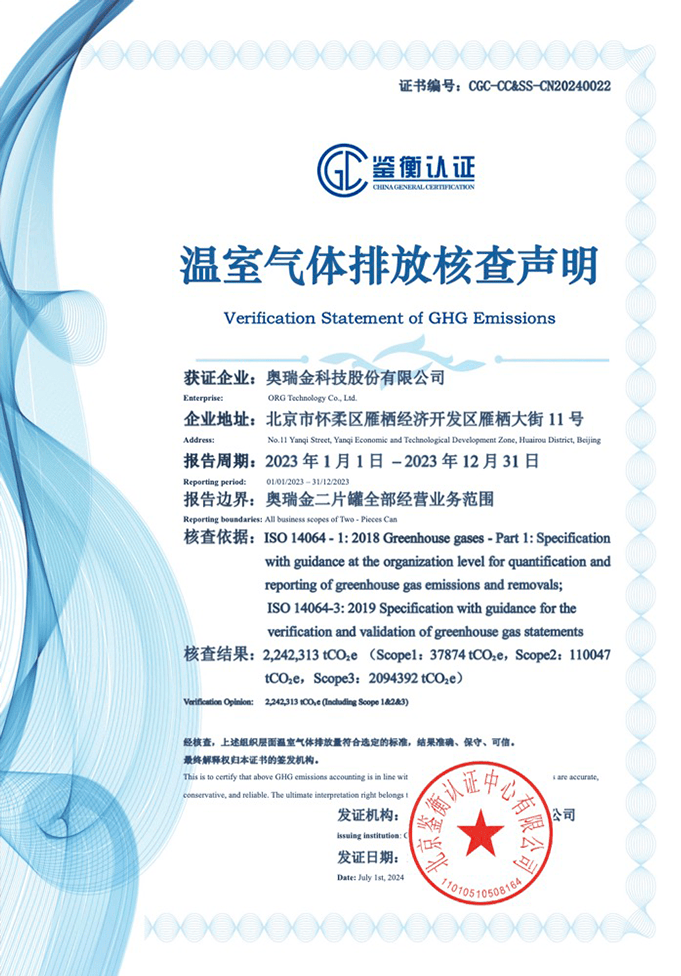

We've also made substantial strides in reducing energy consumption during can production through innovative conveyor belt technology and the increased use of clean energy sources. By implementing equipment upgrades and reducing petroleum content in the sewage treatment plant's incoming water, we've achieved significant water-saving and emission reduction effects.

Xianning Factory liquid ring pump transformation

ORG has set an ambitious long-term goal: to reduce our total carbon emissions by 30% by 2030, compared to our 2018 levels.

As we continue to grow our two-piece can production, ORG is moving forward rapidly, leaving “green footprints” in our wake. Our carbon footprint report stands as a persuasive testament to our efforts, demonstrating how we're firmly fulfilling the "dual carbon" mission that a leading enterprise should bear.

Rebirth through Recycling: Charting New Paths in our “Carbon Footprint Journey”

While the report demonstrates ORG's commitment to sustainability from raw material acquisition through production, manufacturing, and transportation, our low-carbon circular footprint extends even further.

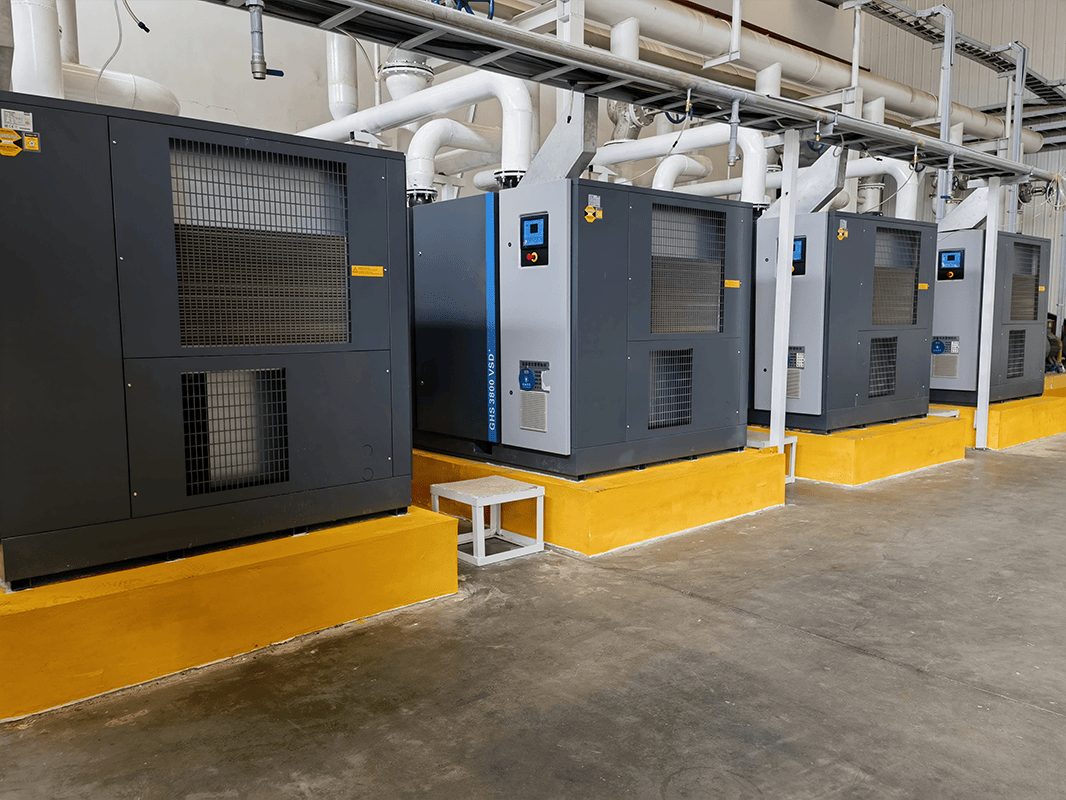

ORG established a packaging material recycling center named Companion Recycle Hub. This innovative facility addresses can recycling through the "primary recycling of used beverage can" project, promoting a "CAN TO CAN" circular economy in metal packaging.

Used cans undergo pre-treatment processes such as waste removal and crushing, transforming them into recycled aluminum. This high-quality recycled aluminum can then be used to produce new cans, creating a closed-loop system that can be repeated multiple times without quality degradation.

This scientific recycling system significantly improves the utilization of waste aluminum, reducing the need for primary aluminum smelting and consequently lowering carbon dioxide emissions.

Through Companion Recycle Hub, we've built a comprehensive environmental protection mechanism based on the process consisting of recycling, sorting, circular processing, and reuse.

In 2023 alone, Companion Recycle Hub recycled over 2.5 billion aluminum cans, equating to 35,500 tons of aluminum. To put this into perspective, recycling one ton of aluminum cans reduces carbon emissions by approximately 1.871-3.171 tons.

ORG's practical actions demonstrate our commitment to exploring higher-value recycling of aluminum can packaging. We're not just providing an innovative solution for sustainable development in the metal packaging industry; we're setting a new standard and direction for the future of carbon footprint reduction in our sector.

Footprints to the Future: Paving the Way for Sustainable Packaging

From our innovations in lightweight cans and lids to the implementation of can recycling machines and the successful operation of the Companion Recycle Hub, we are positioning ourselves at the forefront of industry sustainability.

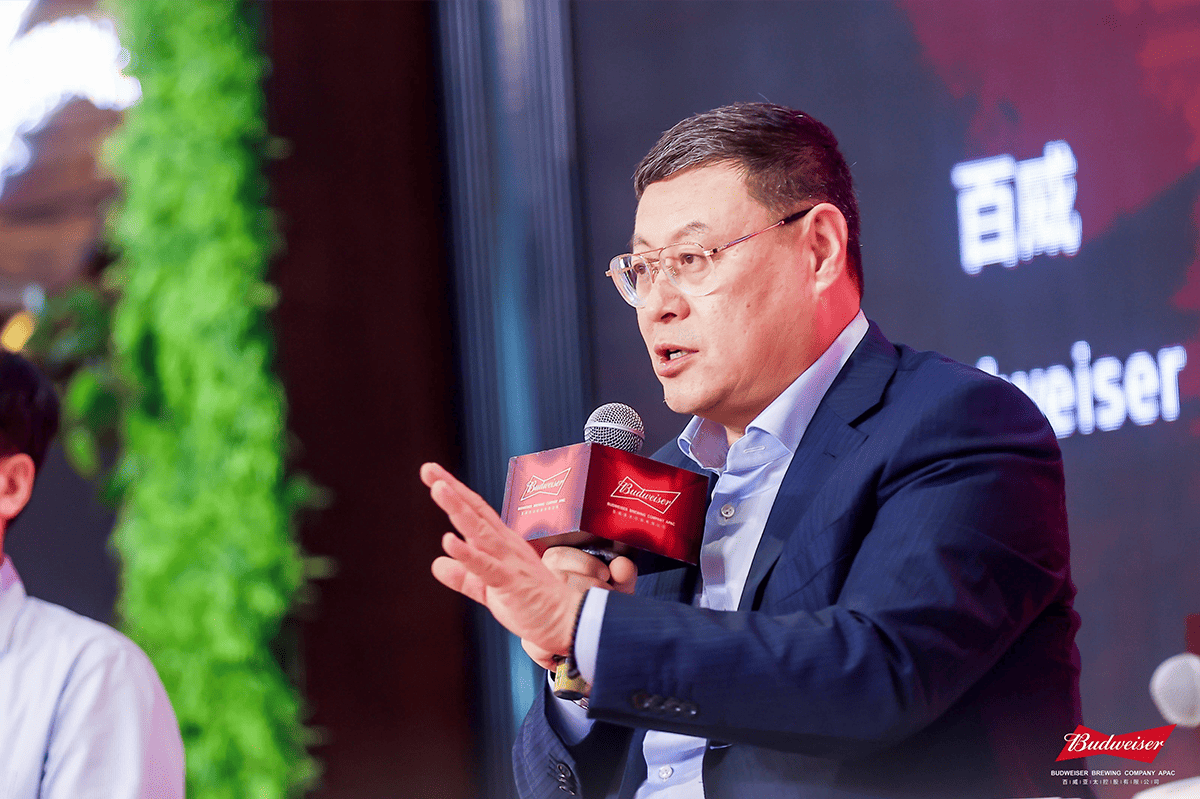

This commitment is deeply ingrained in our corporate philosophy, as eloquently expressed by ORG's Chairman Zhou Yunjie: "When entrepreneurs face the choice between 'profit first' or 'sustainable development first', they must ensure the priority of sustainable development."

These words resonate powerfully, encapsulating ORG's unwavering commitment to a sustainable future.